|

|

|

|

I’ve

had three well pumps burn out in the past 5 years. My plumber says it's a problem with the electric supply, and my electrician

says it’s a pump problem. Who do I believe? This is getting expensive!

|

|

|

Before

tackling this question, a little background information is probably in order: Well pumps are used to draw water from a depth where the water table

is several feet beneath the area of application. In residential settings, there are two main types of well pumps in

use: jet pumps, and submersible pumps.

|

|

|

| Pumping water with a shallow well pump |

|

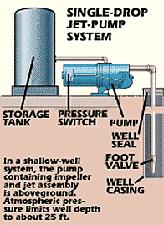

Jet

pumps (sometimes called shallow well or surface pumps) are mounted above the well, either in the home or in a well house,

and draw the water up from the well through suction. Because suction is involved, atmospheric pressure is what's really doing

the work. As the pressure builds, you create a vacuum in the tube above the water. Once the vacuum is there, the weight of

the air, or atmospheric pressure, pushes the water up the straw. Consequently, the height that you can lift the water with

a shallow well is usually limited to a well depth of about 25 feet. Because shallow well pumps use water to draw water,

they generally need to be primed (filled with water) before they'll work. To keep water in the pump and plumbing system from

flowing back down into the well, a one-way check valve is installed in the feed line to the pump.

|

|

|

| Pumping water with a submersible pump |

|

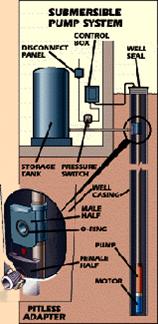

A submersible pump is a long cylindrical

shape that fits inside the well casing. It contains a stacked series of impellers that ‘push’ the water

up the pipe into the house.

Unlike a jet pump

drawing water from above with pressure, the submersible applies pressure below to push the water upward. This also eliminates

the need to prime the pump. This type of pump is best suited for deeper wells. While submersible pumps are more efficient

than jet pumps in delivering more water for the same size motor, pump or motor problems will necessitate pulling the unit

from the well casing. However, submersibles are known for their

reliability and often work flawlessly for 20 years or more without servicing. Submersible pumps may also be used in

shallow water wells but silt, sand, algae, and other contaminants can shorten the pump's life.

|

|

|

Regardless of which pump you use, a residential water system also

requires the use of a pressure tank (also known as a storage, or expansion tank). The function of this device is to store

water pumped from the well for use in the house. The pump pushes water into the tank and that water compresses captive air

in the tank. The air provides continuous pressure for water delivery. The pump recharges water to the pressure tank as needed.

Since most pressure tanks are small, they need refilling often. Pressure tanks in sizes from 20 to over 80 gallons are sold

at hardware and plumbing stores. The primary purpose of this tank

is to extend the life of the well pump. If no tank were present, then the pump would turn on and off every time a faucet was

opened in the house. The larger the storage tank, the less frequently the pump has to start and stop, thereby extending its

life.

One other thing to consider

when purchasing a pump is the rated input voltage. Electric motors can be run on either single-phase or three-phase power.

A three-phase motor is the most efficient type in existence, and it will usually have an extremely long life. However, it

is usually impossible (or at the least, very rare) to have three-phase electric service delivered to a residence, so you’re

most likely limited to a single-phase pump. For most residential applications, single phase pumps come in either a 120 volt

or a 240 volt version. New construction should almost always utilize a 240 volt pump. In older homes, the owner may be limited

to replacing a 120 volt pump with another of the same. However, if possible, when replacing a 120 volt pump you should check

with your electrician to see if a 240 volt replacement could be used. What’s the difference? For one, 240 volts pumps are almost always less

expensive and easier to obtain than their 120 volt counterparts. Also, in some instances a larger GPM rated pump can be connected

to a smaller gauge wire when a higher voltage model is used. Lastly, while often debated, we’re of the opinion that

the 240 volt version will most likely last longer than the 120 volt one.

So, what can cause premature

failure of a well pump? There are several possibilities: Undersized

Well Pump pumps are rated in Gallons Per Minute or GPM. Your pump needs to be

sized higher than the maximum GPM flow calculated for your house. Undersized Storage Tank if your storage tank is too small, then

your pump must work harder to keep a constant supply of water available for your use. As mentioned before, frequent starting

and stopping of any electric motor stresses it and can lead to premature failure. However, once the motor is running it's

in a stable condition. You can keep it running constantly for one minute or one day – it won’t affect its

lifespan. Remember, when selecting a storage tank always try to buy the biggest one you can afford – bigger is always

better! Submersible Pump Set Too Low in the Well A submersible

pump is attached to the end of a pipe and inserted in the well casing. The pump should never sit at the bottom of the well.

A pump that is too far down in the well can pick up foreign debris such as gravel or silt which will eventually cause premature

failure. Low

Voltage Operation When an electric motor operates at voltages less than rated values (undersized

power lines, improper connections, distribution line overloads), the motor will draw additional current in an attempt to produce

the rated horsepower. This increased current flow creates a temperature build-up inside the pump motor. Continued operation

under low voltage conditions will eventually cause the insulation on the motor windings to deteriorate. When winding insulation

deteriorates sufficiently

the motor will short internally, causing it to use more electricity. This also reduces the power output, which further overloads

the motor causing it to fail. This scenario is commonly known as “burning-up.”

|

|

|

In

diagnosing the problem, your plumber can verify the pump size, and the capacity of the pressure tank. If your pump needs to

be pulled, he or she can also examine it to tell if it has been pulling in silt or other debris.

Your electrician can verify wiring, connections, and supply voltage. Most pumps will operate

at the rated supply voltage plus or minus a tolerance of about 10%. Check with the pump manufacturer to be sure. If you are

experiencing a low voltage condition and it is not caused by a wiring problem in the house, then your utility company may

need to get involved to correct the problem. Your electrician should be able to assist you with this problem.

Back to Previous Page

Licensed electricians serving Orange

county, Sullivan county, and Ulster county in New York (845) 888-8000

_________________________________________________________________________________________________ All information contained within this site ©2004-2016, Wurtsboro Electric Service, Inc. All rights

reserved.

Reproducing or duplicating any information contained herein is prohibited by law.

|

|

|

|